- #HEXAVALENT CHROMIUM STAINLESS STEEL HOW TO#

- #HEXAVALENT CHROMIUM STAINLESS STEEL SKIN#

- #HEXAVALENT CHROMIUM STAINLESS STEEL SERIES#

#HEXAVALENT CHROMIUM STAINLESS STEEL SERIES#

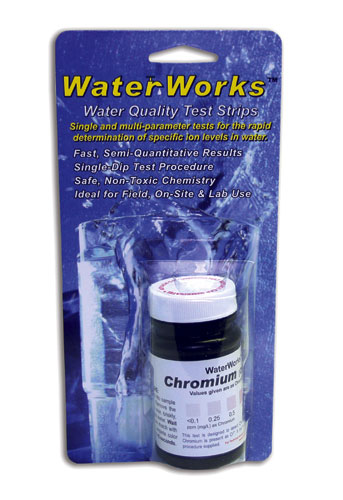

An example of this is Camfil’s Gold Series X-Flo industrial dust collector, which is built to handle all kinds of toxic and combustible dust, smoke and fumes. The best way to control hex chrome fumes in a large space is through a high-efficiency cartridge-style dust collector. This data must reflect workplace conditions that closely resemble the processes, type of material, control methods, work practices and environmental conditions in the facility’s current operations. Objective data is the air monitoring data from industry-wide surveys or calculations that is based on the composition or chemical and physical properties of a substance that demonstrates the employee exposure to hex chrome associated with a particular product or material, or a specific process, operation or activity. The performance-oriented option allows for the estimation of exposures through any combination of air sampling, historical monitoring data or objective data. If the initial monitoring is below these levels, then the company does not have to perform another test unless there is a change in work processes or materials that could result in new or additional exposures to hex chrome. If the immediate monitoring determines that exposure is at or above 2.5 μg/m3, then the company must perform an exposure monitoring test every six months. If the immediate monitoring determines that exposure is at or above the PEL of 5 μg/m3, then the company must perform an exposure monitoring test every three months. The monitoring is performed by employees wearing a small air pump and filter. The scheduled option requires a company to perform exposure monitoring immediately and then periodically depending on certain factors. There are two options to determine exposure:

OSHA does not recommend specific technologies to mitigate risks, however, it does require companies that generate hex chrome to monitor the air to determine the 8-hour TWA exposure for each affected worker. This also includes rules related to preferred methods for controlling exposure, respiratory protection, protective work clothing and equipment, hygiene areas and practices, medical surveillance, hazard communication and record keeping.Įxposure is defined by OSHA as the concentration of contaminants to which an employee would be exposed without using personal protective equipment. The permissible exposure limit for all hex chrome compounds is 5 micrograms per cubic meter of air (μg/m3) as a time-weighted average (TWA) in an 8-hour shift. The Occupational Safety and Health Administration (OSHA) in the United States has permissible limit standards and guidelines determining exposure to protect workers from hex chrome in the workplace. Permissible Limits and Determining Worker Exposure Over time, workers can develop asthma symptoms such as wheezing or shortness of breath. Inhalation at high levels can cause irritation to the nose and throat, damage to mucous membranes, and perforation of septum tissue between the nostrils and nose. Once in the body, hex chrome will usually target organs, including the respiratory tract.

#HEXAVALENT CHROMIUM STAINLESS STEEL SKIN#

However, it can also cause nasal septum ulceration and perforations, skin ulcerations, and allergic and irritant contact dermatitis. Greater risks for lung cancer are the most dangerous health effects related to exposure. Hex Chrome compounds are occupational carcinogens and can cause numerous health issues to workers if they are not protected and the facility not properly maintained. Health Issues Resulting from Hex Chrome Exposure Workers are exposed to hex chrome through inhalation, absorption through the skin or swallowing if they don’t thoroughly wash their hands. The high temperatures involved in allow steel welding result in oxidation of the chromium that changes it to a hexavalent state. It is formed when metalworkers are performing “hot work” such as welding on stainless steel or other alloy steels that contain chromium metal.Ī study conducted by the National Institute for Occupational Safety and Health found that hex chrome is most commonly produced in carbon steel welding, stainless steel welding, painting, electroplating, steel mills, and iron and steel foundries.Ĭhromium is not originally hexavalent. Hex Chrome is a major byproduct of all materials made from chromium.

#HEXAVALENT CHROMIUM STAINLESS STEEL HOW TO#

What makes it dangerous, and what steps can you take to mitigate the risks? Read below to learn about how hex chrome is produced, and how to protect workers at your facility from health issues. This dust/fume can be very dangerous to employees. Hexavalent Chromium is a carcinogenic substance created from different welding and hot metalworking processes.

0 kommentar(er)

0 kommentar(er)